How are products manufactured and transported in a global supply chain

The process of manufacturing and transporting products in a global supply chain can vary depending on the specific product and the specific supply chain. However, there are some general steps that are common to many global supply chains:

The consumer places an order for a product, either online or through a retailer.

The retailer or e-commerce platform sends the order to the manufacturer or supplier, who is responsible for producing the product.

The manufacturer or supplier sources the raw materials and components needed to produce the product. These may come from a variety of different sources and may be located in differentnf countries.

The product is manufactured at the supplier's facility, using the raw materials and components sourced from various locations.

The finished product is inspected, tested, and packaged for transportation.

The product is shipped to a warehouse or distribution center, either owned by the manufacturer or a third-party logistics provider.

The product is sorted and stored in the warehouse or distribution center until it is ready to be shipped to the customer.

The product is shipped to the customer, either directly or through a retailer. The product may be shipped by air, land, or sea, depending on the distance and the speed of delivery required.

Throughout this process, the supply chain management team is responsible for coordinating the flow of materials, information, and finances between all of the organizations and activities in the supply chain. They use a variety of tools and techniques, such as demand forecasting, inventory management, and transportation planning, to ensure that the right product is delivered to the right place at the right time in the most cost-effective way possible.

The story of a sofa, beginning to end

1. A consumer orders from a website

A consumer visits the website of their local furniture store (a national chain, ex Ashley Furniture) website and orders a sofa. The sofa is out of stock, but the consumer is willing to wait for the sofa and they place an order.

2. Retailer places a bulk order for sofas

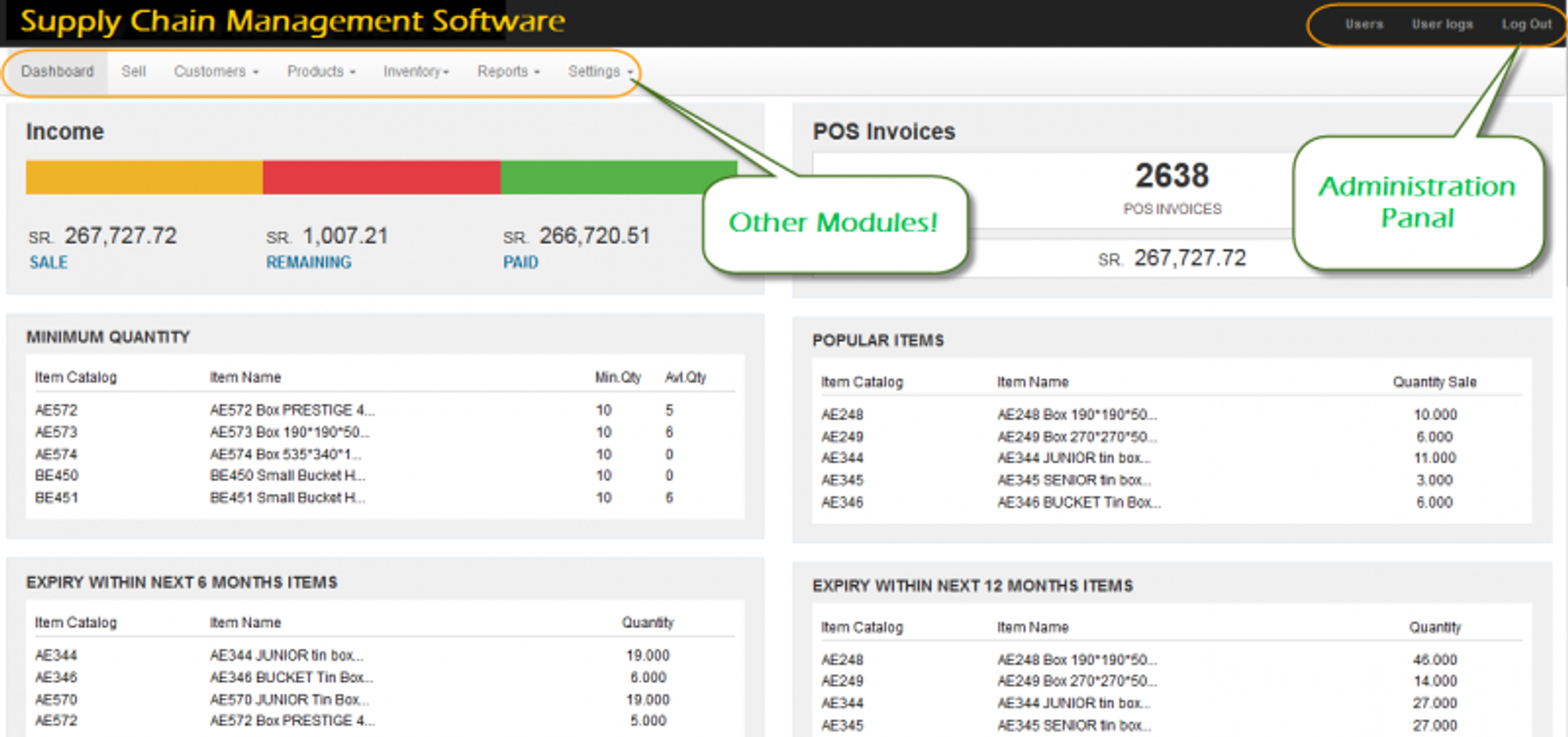

The sofa is out of stock, but it has just been featured in a fancy furniture catalog. The furniture retailer predicts that this will drive up the demand, and places an order for 1,000 sofas using a supply chain management software (SCM).

3. Notifying manufacturers

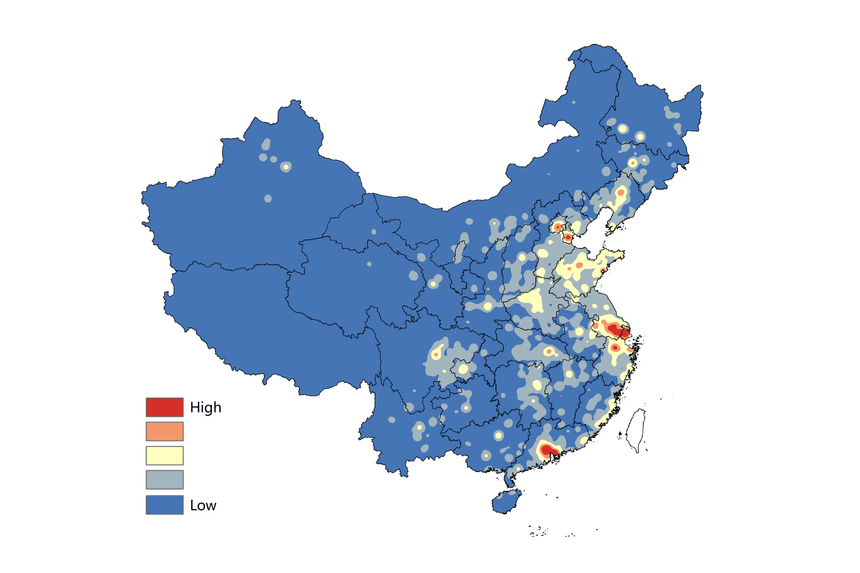

The SCM notifies the suppliers, manufacturers, and distributers of the request. The product is sourced and manufactured in China through arrangements the retailer has with Chinese furniture builders.

4. Manufacturers source raw materials

The Chinese manufacturer calculates the quantity of raw materials needed to build the sofa and then requests it from upstream suppliers. Some of the supplies needed include wood, fabric in various colors, foam, fastenings, etc.

5. Upstream suppliers

The upstream suppliers for the sofa materials may, in turn, request further raw materials. For example, the fabric manufacturer will need to source cotton and dyes to manufacture the fabric.

6. Local logistics companies deliver raw materials to the manufacturer

Once the factory has the raw materials they need, they begin manufacturing. After they finish building the sofas, they load and secure them into shipping containers and dispatch the goods for intercontinental shipping.

7. Intermodal shipping to the port

An intermodal logistics provider coordinates trucks and trains to load and transport the sofas through China via road and rail. The goods are taken to a port in Shanghai and stored before loading onto a container ship bound for the U.S.

8. Dealing with customs

Before the containers can be loaded and transported, customs and other paperwork is completed and filed. A freight forwarder or customs broker prepares necessary paperwork, including declaration of goods, necessary customs duties that need to be paid, bills of lading, etc. After completion, the goods are loaded onto the container ship, into space leased from an international carrier.

9. A port in the US receives the products from the container ship

10. A Third-party logistics provider (3PL) uses its contracted warehouses to store the retailer's products

11. Delivery to home (or to a retailer such as Walmart)

A specialist truck designed for transporting furniture picks up the sofa and delivers it to the customer’s house.

Domestic freight landscape

First, middle, and last mile

1. First-mile: from the raw material to the manufacturing

2. Middle-mile (that's us!): from the manufacturer (the shipper) to the retailer to the e-tailer

3. Last-mile: from the distribution center to the consumer (think the Ashley furniture distribution center to your home)

So... where do we fit in?

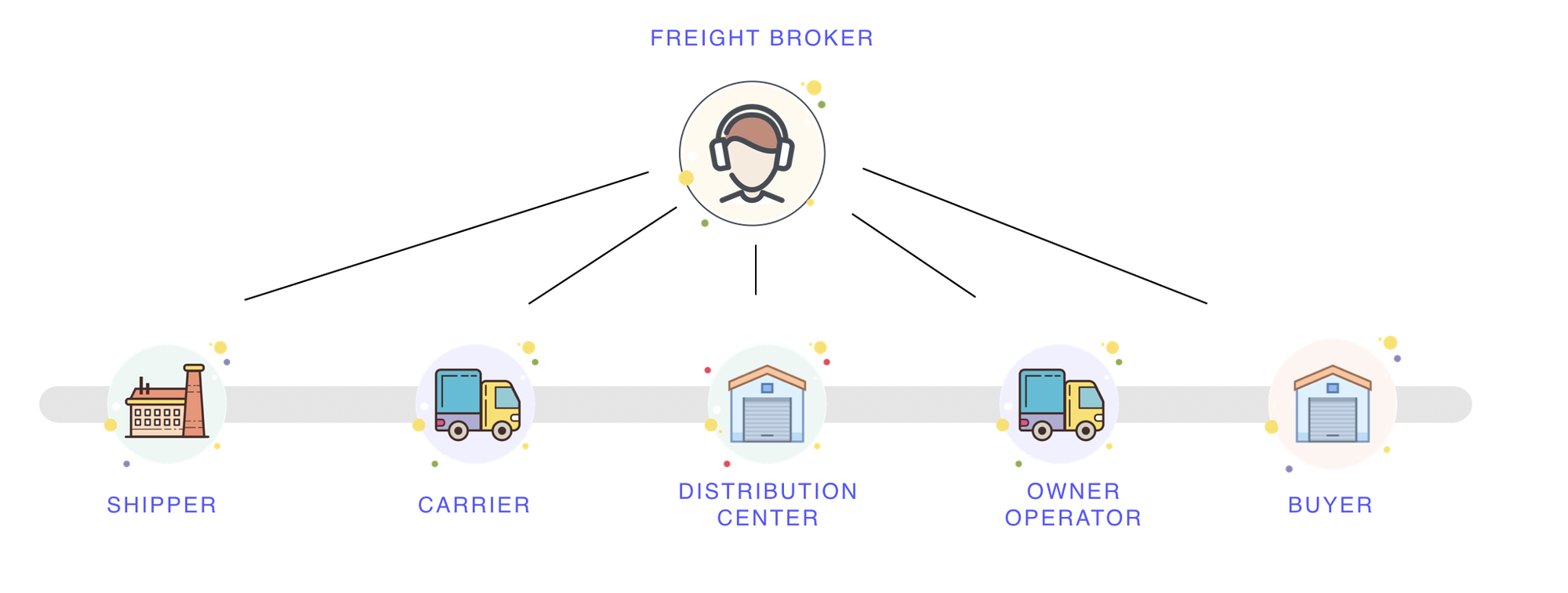

Middle mile logistics, FTL, and our customer is the freight broker

- The shipper is our customer's customer, the person producing the goods and selling them

- This is the carrier. They are responsible for delivering the load. The broker finds a carrier to pick up the load from their customer (the shipper), and take it to the buyer (the person who ordered it from the shipper)

- The buyer (a store or another warehouse) is the stakeholder that purchases items from the shipper. This is our customer's customer's customer.

Scenario

Your family has been in the welding industry for a century. You are a small tool manufacturer, and you make some of the best tools in the country. Your primary focus is on craftsmanship and figuring out how to produce the finest tools. More and more hardware stores are finding out about your tools and placing orders. To distribute your tools, you have been finding trucks yourself to take the tools to the store. But now that more orders are being placed, and the orders are coming from across the country, distributing your tools is becoming extremely hard to manage. In fact, in order to manage this process yourself, you would have to hire a whole team of people solely to find trucks, and make sure they get to your very demanding buyers on time. Your experience is in fine craftmanship, not logistics. On top of that, distribution is becoming a big distraction to your business.

Our customer

This is where the freight broker comes in. A shipper calls a freight broker and tells them when the shipment will be ready, and everything is taken care of. The freight broker is responsible for finding a truck to pick up the load at the best price, making sure that the truck gets to the destination on time, and managing any issues in between.

Load life cycle

An order comes in from the shipper. Shippers can send a request to a single broker or to many brokers they work with. This can be done by sending an email from TMS or oftentimes, they are sending emails manually.

The freight brokers then compete to find a good price to win the Shipper's bid. They will call their network of carriers and request price to then quote to the shipper. Other than calling, they are posting on different websites (called Loadboards), sending out mass-emails, and trying every possible way to get the best rate. Then they negotiate a rate with a Truck carrier, confirm with the Shipper, and book the truck.

The freight broker sends the carrier dispatch information via the broker's TMS. There is a lot of planning that happens after a truck is booked and before the load is picked up.

The carrier is on the way to the shipper to pick up the load (what are they responsible for now, what could go wrong). Before arriving at pickup, there are many issues that can go wrong, and this is where the broker will be involved the most, to ensure the truck arrives and picks up the load. Issues that can happen are 1. The truck does not get unloaded at the previous shipment, 2. the truck breaks down, 3. there is a delay due to traffic as trucks have to go from their previous delivery point where they are unloading to the next load, 4. the carrier can decide to go pick up a more higher-paying load (this is very BAD practice if carriers do this and this can ruin relationships), 5. the truck driver runs out of hours because they are only allowed to legally remain On-duty to work for 14 hours (11 of which can be done only for driving).

Then, the carrier picks up the load and is now on the way to the destination

In transit is when the carrier is on the way to the delivery point. Usually, this can be 1-6 days in transit as some trucks go across the country. The broker will use a combination of mobile app tracking and also calling to make sure everything is going smoothly (at least 1-2 calls per day).

The load arrives at the warehouse (buyer), for delivery. After, the truck will get unloaded. Usually, the truck will already have the next load assigned to them and will head there as soon as they are empty. If they have delays unloading or hit traffic on the way to the next pickup, the next load's broker may cancel the truck and start looking for another one because oftentimes the load will need to be picked up that day.

The carrier picks up the load, and is now on the way to the destination.

Note: along the way the buyer might ask the shipper where the shipment is. In turn, the shipper asks the broker where the load is. In turn, the broker (our customer) must get ahold of the driver and find out where the load is. Then, the information is relayed back to the shipper, who relays it back to the buyer.